With the rapid development of modern industry, especially in the plastic and rubber processing industries, twin-screw extruders, as important production equipment, have a decisive impact on product quality and production efficiency in terms of their performance and stability. As one of the key components of the twin-screw extruder, the heater plays a crucial role in it. This article will delve into the importance and technical characteristics of twin-screw extruder heaters in the production process.

1、 Overview

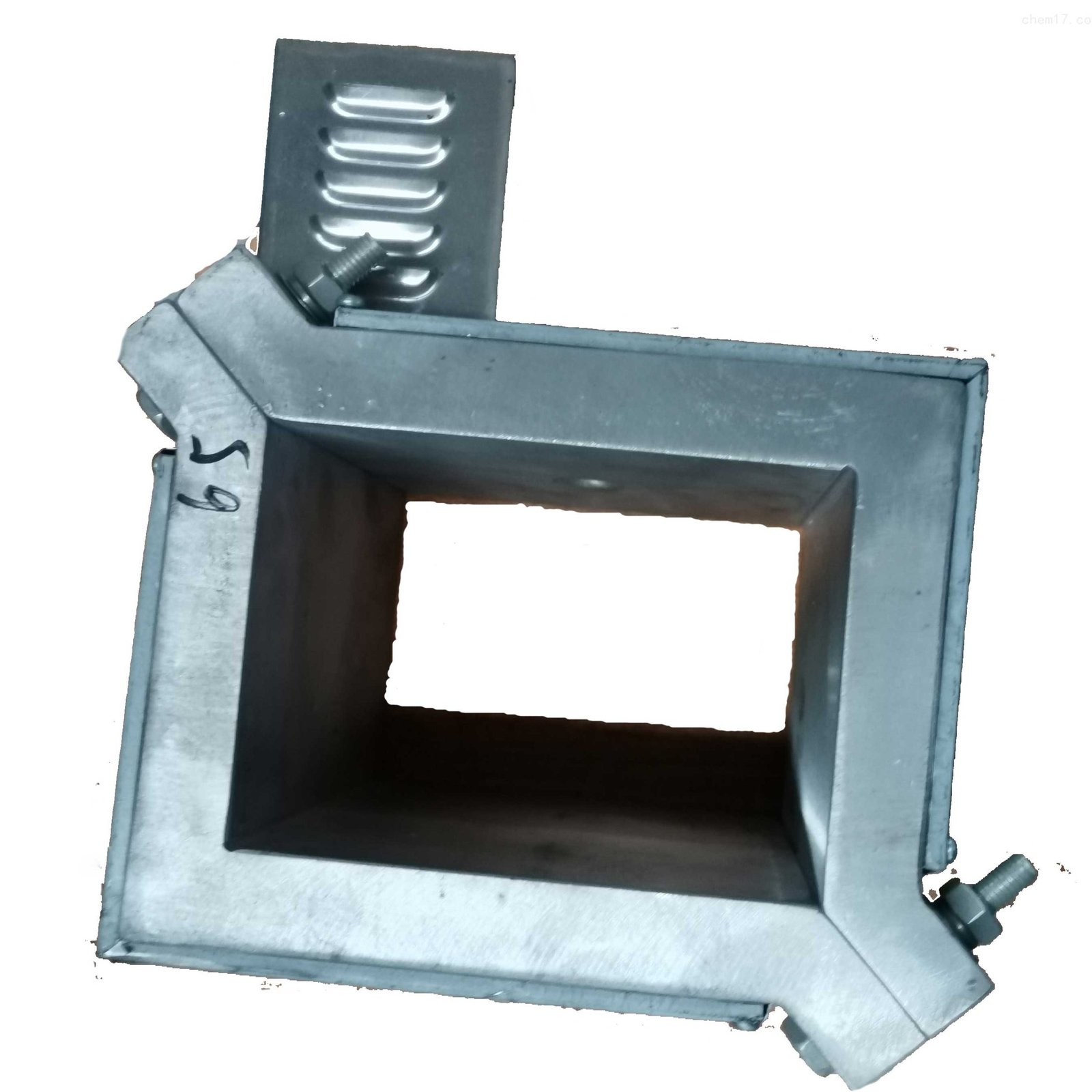

The twin-screw extruder heater is an important device used to heat twin-screw extruders. Its main function is to provide the required heat for the material during the extrusion process, so that the material can reach a molten state and meet the requirements of subsequent molding and processing. Heaters are usually made of high-quality materials such as cast copper or cast aluminum to ensure uniform and rapid heating, as well as long-term stable operation.

Two technical characteristics

1. Efficient heating: With efficient heating performance, it can heat materials to the desired temperature in a short period of time, improving production efficiency. At the same time, its heating uniformity can ensure that the material will not experience local overheating or undercooling during the heating process, thereby ensuring the quality and stability of the product.

2. Energy conservation and environmental protection: With the continuous improvement of environmental awareness, energy conservation and environmental protection have become an important trend in modern industrial production. The design fully considers energy-saving factors, adopts heating technology and insulation measures, effectively reduces energy consumption and heat loss, and achieves the goal of energy conservation and environmental protection.

3. Intelligent control: Modern devices are generally equipped with intelligent control systems, which can control parameters such as heating temperature and heating time. This can not only improve the automation level of the production process, but also flexibly adjust according to the properties of materials and production needs, further improving production efficiency and product quality.

3、 Application and Development

Twin screw extruder heaters are widely used in the processing of polymer materials such as plastics and rubber. With the continuous development of the polymer materials industry, the performance requirements for extruders are also increasing. Twin screw extruders have gradually become equipment in the polymer material processing industry due to their advantages, such as small material changes, uniform mixing, and stable pressure. As one of the core components of twin-screw extruders, the stability and efficiency of the heater’s performance are crucial for improving product quality and production efficiency.

In the future, with the continuous advancement of industrial technology and the intensification of market competition, we will face higher requirements and challenges. On the one hand, it is necessary to continuously improve the heating efficiency, energy-saving and environmental performance, and intelligent control level of the heater; On the other hand, customized design is also needed for different materials and production needs to meet the personalized needs of more customers.

4、 Conclusion

In summary, as an important device in modern industrial production, the stability and efficiency of the performance of twin-screw extruder heaters are of great significance for improving product quality and production efficiency. With the continuous advancement of technology and changes in market demand, it will continue to play an important role and usher in broader development prospects in the future.